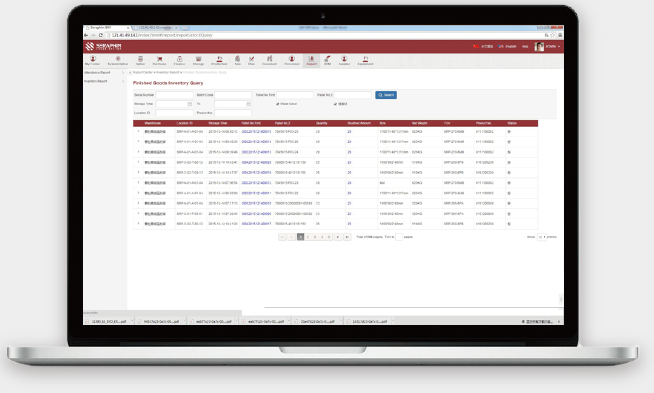

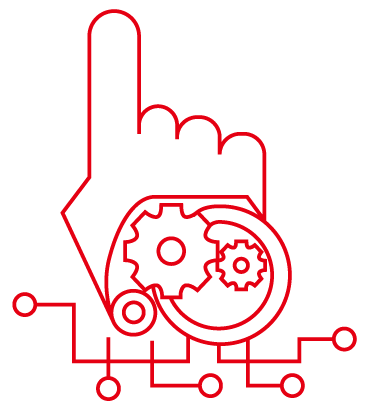

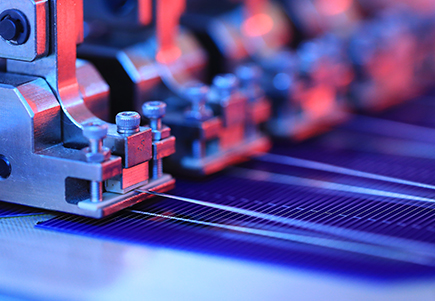

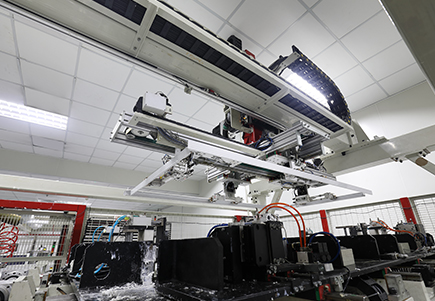

Highly automated production lines enable Seraphim to supply modules with consistent quality, fast delivery and low cost. Seraphim strives to meet all of clients’ expectations by utilizing fully automated manufacturing facilities, advanced quality control systems, and self-developed fully transparent quality management systems.

Automatic Cell Selection

Automatic Raw Material Feeding

Automatic Cell Soldering

Automatic Layering

Automatic Lamination

Automatic Framing

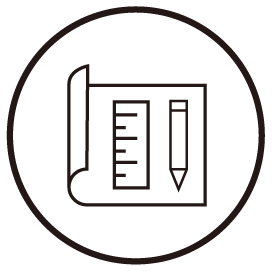

-

storage

storage

-

Purchase

Purchase

-

Finance

Finance

-

Plan

Plan

-

Sale

Sale

-

Report

Report

-

Equipment

Equipment

-

Production

Production